The chemical industry is generally defined as "an industry that manufactures products from various materials for various purposes by using chemical technology". Chemical products are classified broadly as inorganic chemical products, gas products, organic chemical products, and petrochemical products, etc.

In the chemical industry process, amorphous solids (powder and grain) and fluids (liquids and gases) are put into devices (containers) under certain conditions (temperature, pressure and catalysts), which perform chemical alterations (chemical technology). The elements that constitute these process facilities (process units) are stationary equipments (towers, vessels and heat exchangers) and revolving equipments/dynamic equipments (pumps, compressors, and centrifugal machines).

In the chemical industry process, the measure against corrosion, which is caused by corrosion factors and reaction by-products that are unpreventable in the reaction process, frequently become an issue. When faced with corrosion (deterioration) of materials, people involved in the chemical industry may often have to consider how to reduce or prevent corrosion. Examination of anticorrosion measures is to be based on the factors of construction design, environmental control, material selection and the combination of the factors. Our Corrosion Resistant Alloys site has been made to be useful in choosing a material for all, including people not specialized in the area of corrosion resistance. Please access our site for more information.

The materials that are generally used for chemical devices are diverse, ranging from iron and steel materials such as carbon steel and stainless steel, nonferrous materials such as Ni, Ta, Zr and Ti alloys, etc, as well as nonmetal materials such as glass lining, resin lining, and carbon (impervious graphite), all of which have distinct features.

Recently, to improve productivity of the plants, there is a tendency to extend intervals between periodic maintenance. Needless to say, facilities aiming for continuous operation need to secure the long-term soundness of plant material. This means that the approach to material selection is changing from an emphasis on initial cost to a selection of highly reliable material that creates a maintenance-free environment. Our special corrosion-resistant alloys and heat-resistant alloys are highly appreciated for their properties that ensure enough corrosion resistance required for the intended plant environment. Furthermore, our alloys offer great performance in designing and constructing of clad steel plate, and lining, reliability in fabricated equipments as well as economical efficiency.

MMC Superalloy manufactures various heat-resistant alloys, corrosion-resistant alloys, and wear-resistant alloys such as MAT21 (developed by our company), MA alloys, BISHILITE (Mitsubishi Materials Hard-Facing Alloys), etc. These alloys are highly used and appreciated as materials for various devices and piping in such chemical processes as the following.

(Caustic soda, sulfuric acid, hydrochloric acid, nitric acid, hydrofluoric acid, chlorine, phosphoric acid, zinc chloride, ferric chloride, aluminum sulfate, etc)

(Acetic acid, ethylene dichloride (DEC), vinyl chloride monomer (VCM), trichloroethylene , epichlorohydrin (ECH), isopropyl alcohol (IPA), acrylonitrile (AN), methyl isobutyl ketone (MIBK), methyl ethyl ketone (MEK), cyclohexanol, styrene monomer (SM), methyl methacrylate (MMA), high-purity terephthalic acid (PTA), tolylene diisocyanate (TDI), diphenylmethane diisocyanate (MDI), high-density polyethylene (HDPE), polycarbonate (PC), polyphenylene sulfide (PPS), etc)

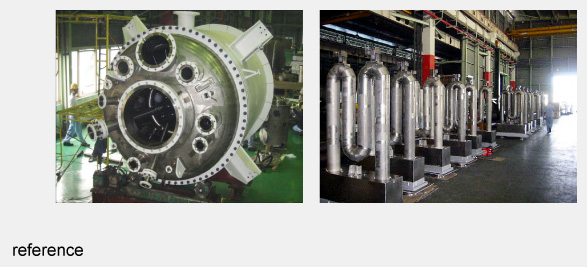

Our corrosion-resistant alloys used in the typical chemical processes can be produced into materials such as plates, bars, wires, and also various fabricated products by making full use of our excellent processing technology. We keep trying our best to be regarded by our customers as a trustworthy manufacturer.

Fabricated products are produced at PT. MMC METAL FABRICATION (abbreviated as MMF), a special alloy fabricator (weld-assembly-products manufacturer) which was established in 1997 by our predecessor Mitsubishi Materials Corporation in Indonesia.